PLASTIC MOULDING

MOULD CONSTRUCTION AND PERSONALISATION

Welcome to the world of perfect closure

CO.Plast s.r.l. was founded almost fifty years ago and specialises in the moulding of plastic materials and manufacturing plastic closures for bottles, deodorant containers, wet wipes and other products to supply the pharmaceutical, cosmetics and household goods markets.

Company

CO.Plast s.r.l. is located in the green Brianza region. Our headquarters, spread over 6000 square metres, is located in Barzago.

Quality

CO.Plast s.r.l. always aims for quality in manufacturing plastic bottle closures. Our company operates according to UNI EN ISO 9001 - 2015.

Production

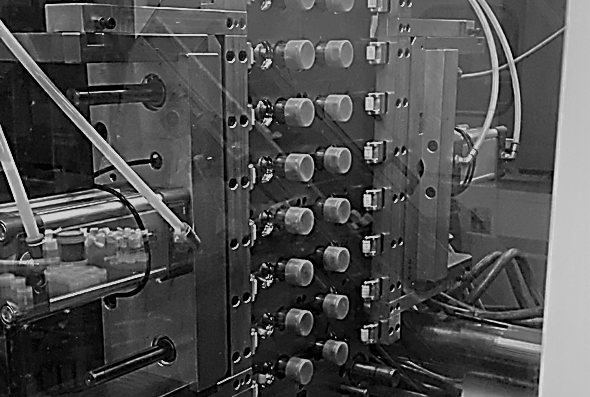

Our company has two production lines, in-line with automatic weighing and packaging units.

Industry 4.0

We have always integrated new production technologies to improve production control.

Slide title

Write your caption hereButton

| PRODUCTION PROCESS |

Industry 4.0

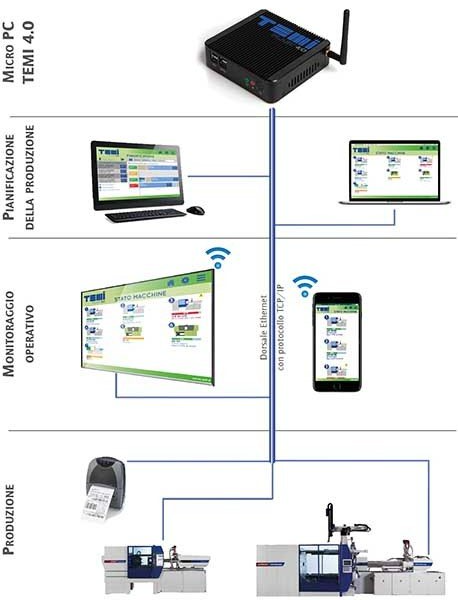

As part of Industry 4.0, CO.Plast uses the best-selling system for plastics companies in Italy in 2017. TEMI Plast 4.0 was created for companies operating in the plastics processing sector and allows the production process to be organised and monitored automatically, easily and effectively.

TEMI aids production monitoring from the entry of an order through the allocation of the production batch process data extrapolated from the individual machines and ending with the printing of a label or QR code indicating the overall characteristics stored in the production server. The architecture developed in web-browser and tcp/ip communication language allows TEMI's software to be visualised on a variety of media, guaranteeing flexibility and versatility. The secure archiving system also allows the company to comply with the most stringent international standards for quality assurance and product traceability.

| QUALITY |

Production phases

DESIGN

Artfully designed

Our specialised team designs each product in partnership with the customer, following the following steps

- product design;

- mould design and construction;

- environmental protection;

- production planning;

- 100% customer satisfaction.

MEASUREMENT

Measuring is an art

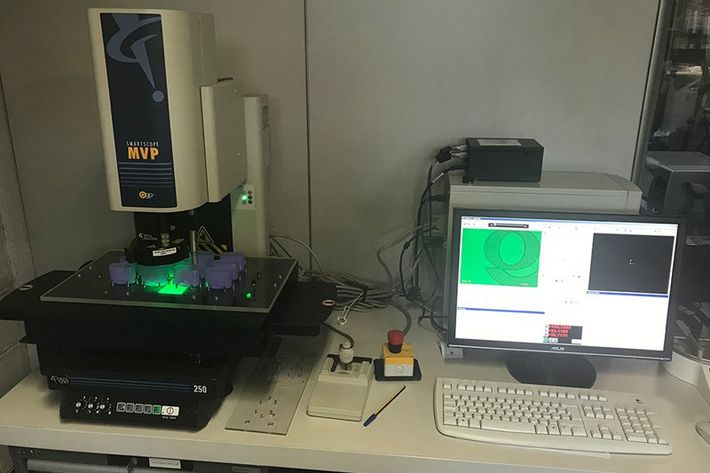

We design our measurement systems to the best of our ability:

- appropriate 'control plans' for each product family;

- measurements using innovative optical technology;

- leak tests on the caps we produce;

- measurement reports;

- traceability to calibration standards.

STATISTICS

Artfully analysing

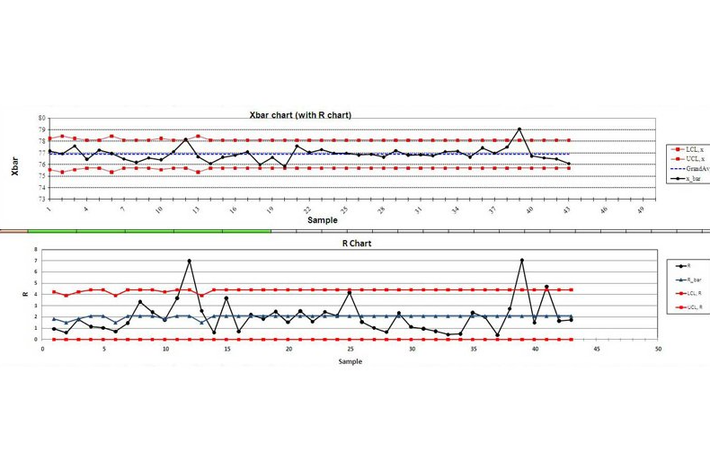

We use statistics to guarantee the quality of each product through:

- statistical reports of production trends;

- statistical measurement trend reports;

- statistical process control;

- improvement study;

- pursuit of perfection!

| Certifications |

'Quality is never accidental, it is always the result of intelligent effort'

Address

Via Provinciale La Santa 7,

23890 Barzago (LC)

Powered by ItaliaOnline - Pagine Gialle